Our Company

LATEST NEWS

Agnitron joins the 2024 US Gallium Oxide Workshop in Columbus, OH

Agnitron Showcases Groundbreaking Research at GOX 2024 Columbus, OH — Agnitron Technology made a significant contribution at GOX 2024, the 7th U.S. Gallium Oxide Workshop [...]

Agnitron to attend the upcoming 21st International Conference on Metal Organic Vapor Phase Epitaxy (ICMOVPE XXI) delivering four presentations.

The 21st International Conference on Metal Organic Vapor Phase Epitaxy (ICMOVPE XXI) is scheduled for May 12-17, 2024 in Las Vegas, Nevada. Agnitron will be [...]

Agnitron Scientists to present at the WOCSEMMAD 2024 in Las Vegas, NV

Agnitron Technology is a key sponsor for the upcoming Workshop on Compound Semiconductor Materials and Devices (WOCSEMMAD) to be held in Las Vegas, NV Feb21-23, [...]

MOCVD

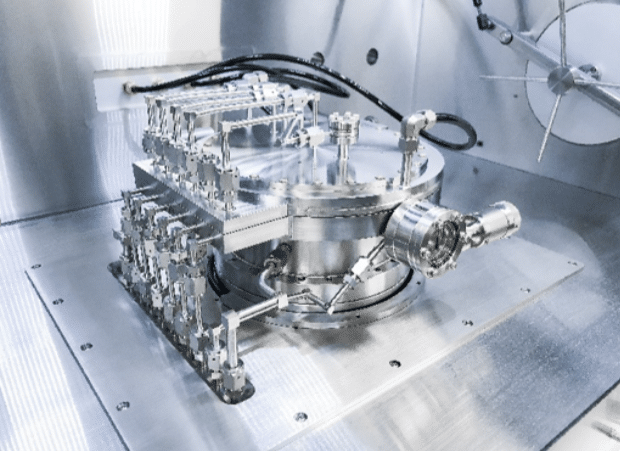

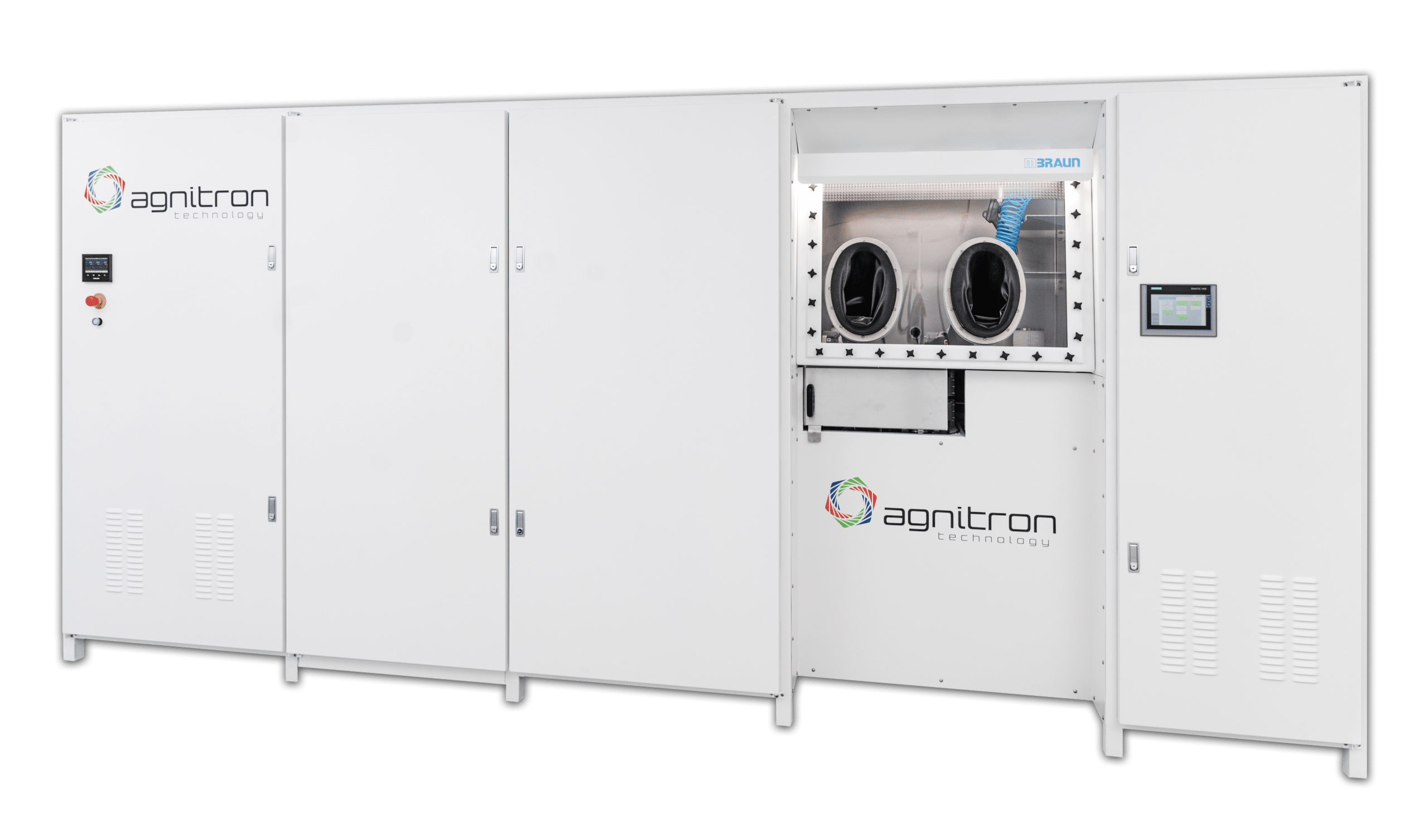

GOX Series 300

Agilis GOX series equipment can be configured to grow Gallium Oxide and AlGaO alloy-based material systems. Agnitron tools are installed on 4 continents growing world-class wide bandgap material for power devices for numerous labs. Record breading Ga2O3 wide-bandgap materials has been achieved on the Agilis GOX series tools.

Control Software and Automation

Imperium-MOCVD™ Control Software and Automation is a modern Windows operating system based SCADA package for controlling MOCVD equipment and processes. It was developed for extending the life of Legacy MOCVD systems and upgrading these large capital investments with state of art control and data logging capabilities. Imperium-MOCVD™ is a direct replacement for Legacy Emcore, Veeco, Thomas Swan, Aixtron and Structured Material Inc. (SMI) OEM Control Software and Automation and offers many new features setting a new bar for MOCVD control flexibility.

Insitu Monitoring

The Agnitron AgniTemp Multiwavelength Pyrometer. Combines speed and precision, enabling accurate, repeatable measurement and control in demanding MOCVD applications. The high-speed performance is ideal for processes with high susceptor rotation speeds. The AgniTemp unit is remarkably compact and supports multiple simultaneous wavelength measurement. The emissivity corrected pyrometer measures and controls wafer surface temperatures for repeatable, accurate and precise growth process. It provides increased yields due to excellent wafer-to-wafer and run-to-run temperature repeatability and control, eliminates process drift, provides quick turn-around after maintenance, and ensures tools higher uptime.