AgniTemp™ Technology

High Speed Multiwavelength Pyrometer.

Accurate wafer temperature monitoring and control in MOCVD applications.

The Agnitron AgniTemp Multiwavelength Pyrometer

Combines speed and precision, enabling accurate, repeatable measurement and control in demanding MOCVD applications. The high-speed performance is ideal for processes with high susceptor rotation speeds. The AgniTemp unit is remarkably compact and supports multiple simultaneous wavelength measurement. The emissivity corrected pyrometer measures and controls wafer surface temperatures for repeatable, accurate and precise growth process. It provides increased yields due to excellent wafer-to-wafer and run-to-run temperature repeatability and control, eliminates process drift, provides quick turn-around after maintenance, and ensures tools higher uptime.

Product Highlights

- Non-contact temperature and reflectance measurement of wafer surface and carrier

- Available wavelength customization

- Seamless integration with Agnitron Imperium process control and management Control Software and Automation

- 930nm wavelength temperature and reflectance measurements can be combined with available simultaneous 405nm and 630nm wavelengths reflectance measurements

Advantages

- Provides real time temperature, reflectance, growth rate and layer thickness

- Eliminates temperature variations due to thermocouples positioning and other factors, guaranteeing exceptional growth process repeatability, accuracy and stability

- Allows quick on-the-fly temperature adjustments after reactor maintenance, wafer or wafer carrier changes

- Integrated with Agnitron Imperium process control and management software for automatic data capture triggering, individual recipe layer begin and end timing, and other process information

- Data snapshots and layer thickness measurements could be triggered by selected layers during recipe execution

- AgniTemp Metrology software package calculates growth rates and layer thickness in real time during material deposition

- Single device uses one viewport for all supported temperature and reflectance measurements

- Single AgniTemp control PC can simultaneously control multiple optical heads for multiple temperature and reflectance measurements

- High data acquisition rate allows collecting 10,416 temperature and reflectance data points every second providing 5,208 distinct data points per revolution at 120 RPM susceptor speed and 521 distinct data points per revolution at 1,200 RPM susceptor speed

- AgniTemp Metrology Package software provides temperature and reflectance distribution profiles along the curve on the wafer surface traversed by the optical head for each observed wafer or any selected portion of the observed wafer

AgniTemp™ Software

Supports Simultaneous Temperature and multiwavelength Reflectance Measurements

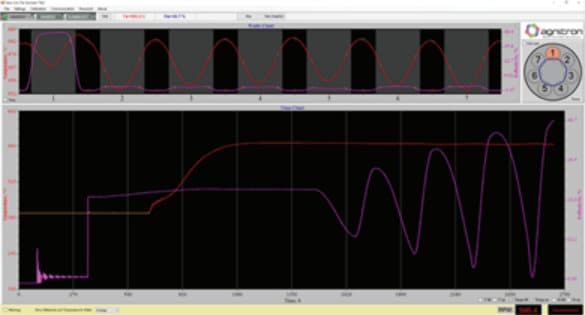

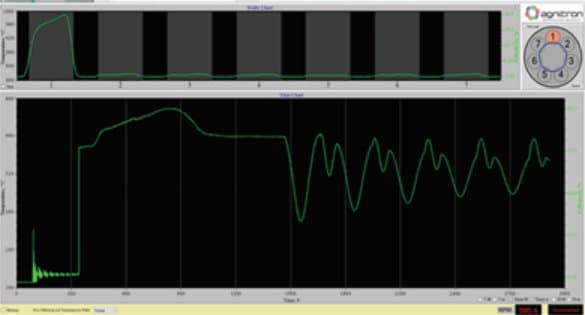

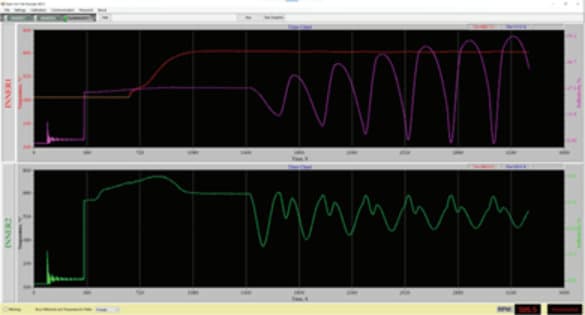

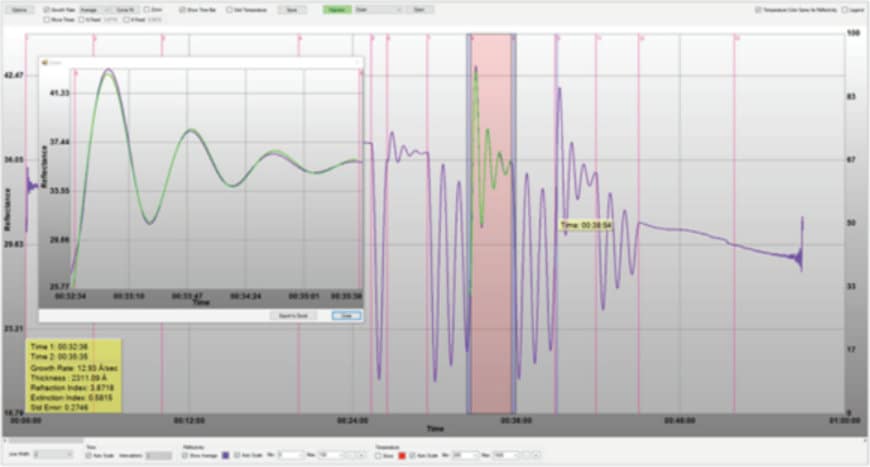

Screenshots illustrate simultaneous measurements of the temperature and reflectance at 930nm and custom reflectance at 525nm.

AgniTemp Software Features

- Measuring average temperature and reflectivity on the surface of all wafers in the growth run

- Measuring average temperature of the carrier surface when gaps between wafers are sufficiently large

- Observing and on-screen real-time plotting of the average temperature and reflectivity of all the wafers surfaces and the temperature of the carrier surface

- Observing and on-screen real-time plotting of the average temperature and reflectivity of any selected wafer surface

- Zooming on any portion of the real-time reflectivity and temperature plots

- When the Agnitron Imperium software runs a recipe an automatic synchronization of the recipe layering information and the real-time data plots on the Lambda-ECP computer is supported

- Using the software measuring tool to measure the film growth rates and thickness during the execution of the recipe

- Saving the data from a recipe run for further analysis and processing

- Integrate with the AgniTemp Pyrometer Software or can be used separately offline

- Ability to precisely measure layer thickness and observe the goodness of measuring process curve fit

- Total customization of all graphical elements including backgrounds, lines, colors, gridlines, time, and scales of measurement

- Ability to simultaneously display all wafer data for any selected subset of wafers for both reflectivity and temperature independently as well as the average over all wafers

- Ability to set up the reflective index and the extension coefficient manually or to let the software configure them automatically

- Off-line stand-alone curve-fitting and data measuring software included

- Switch between different optical head and/or wavelength by selecting a tab in the software

- Ability to compare a related recipe temperature and reflection by templates against the currently executing recipe

- Capture of screenshots can be performed or driven by the recipe execution

- Flexible time scaling with zooming on any desired portion of the growth process

Provides Complete Metrology Package

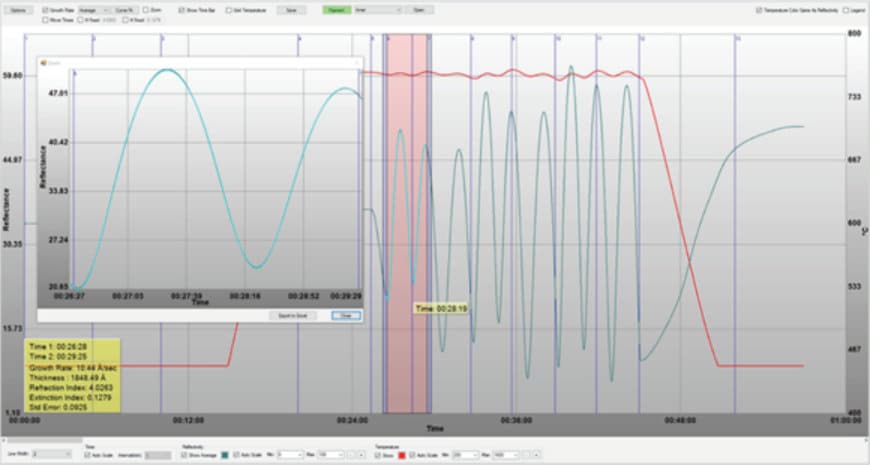

AgniTemp Metrology Package screenshots illustrate the results of measuring the growth rate at a selected recipe layer and the thickness of the layer at 525nm and at 930nm.

A zoom window illustrating curve fitting at the 930nm and 525nm are also displayed.

AgniTemp™ Specifications

Agnitron offers state-of-the-art, customizable OEM and Legacy R&D MOCVD and CVD solutions combined with decades of material science, and equipment and process engineering expertise. These solutions are offered while leveraging experience refurbishing, upgrading and remanufacturing R&D scale MOCVD systems worldwide.

| Configurations | Temperature and reflectance at 930nm only |

| Temperature and reflectance at 930nm and reflectance at 635nm | |

| Temperature and reflectance at 930nm and reflectance at 405nm | |

| Temperature and reflectance at 930nm and reflectance at 635nm and 405nm | |

| Temperature Range* | 450°C to 1,200°C |

| Typical Accuracy | 1.0°C |

| Typical Repeatability | 0.1°C |

| Resolution | 0.1°C |

| Reflectance Accuracy | 0.5% |

| Reflectance Repeatability | 0.5 % |

| Mounting | External or integrated Gimbal mount with optional X/Y table |

| Data Acquisition Rate | 10.4 kHz data transfer rate for 4 simultaneous data streams |

| Environmental | 18°C to 45°C non-condensing operation |

| Typical Application Materials | AlGaN, AlGaAs, InGaN, AlInGaP, Ge, InP, GaAs, Si3N4, Si, SiC, InGaAs, InGaAsP |