Agnitron Technology installs two additional MOCVD systems for university customers!

Agnitron Technology, of Chanhassen, Minnesota, USA, the leader in custom MOCVD systems in the USA, has successfully installed two custom MOCVD systems this summer. The first tool is for growing ultra-wide band gap (UWBG) Ga2O3 for power and RF devices at University of California Santa Barbara, CA. The second is for wide bandgap (WBG) SiC devices for quantum computing at Notre Dame University, South Bend, IN.

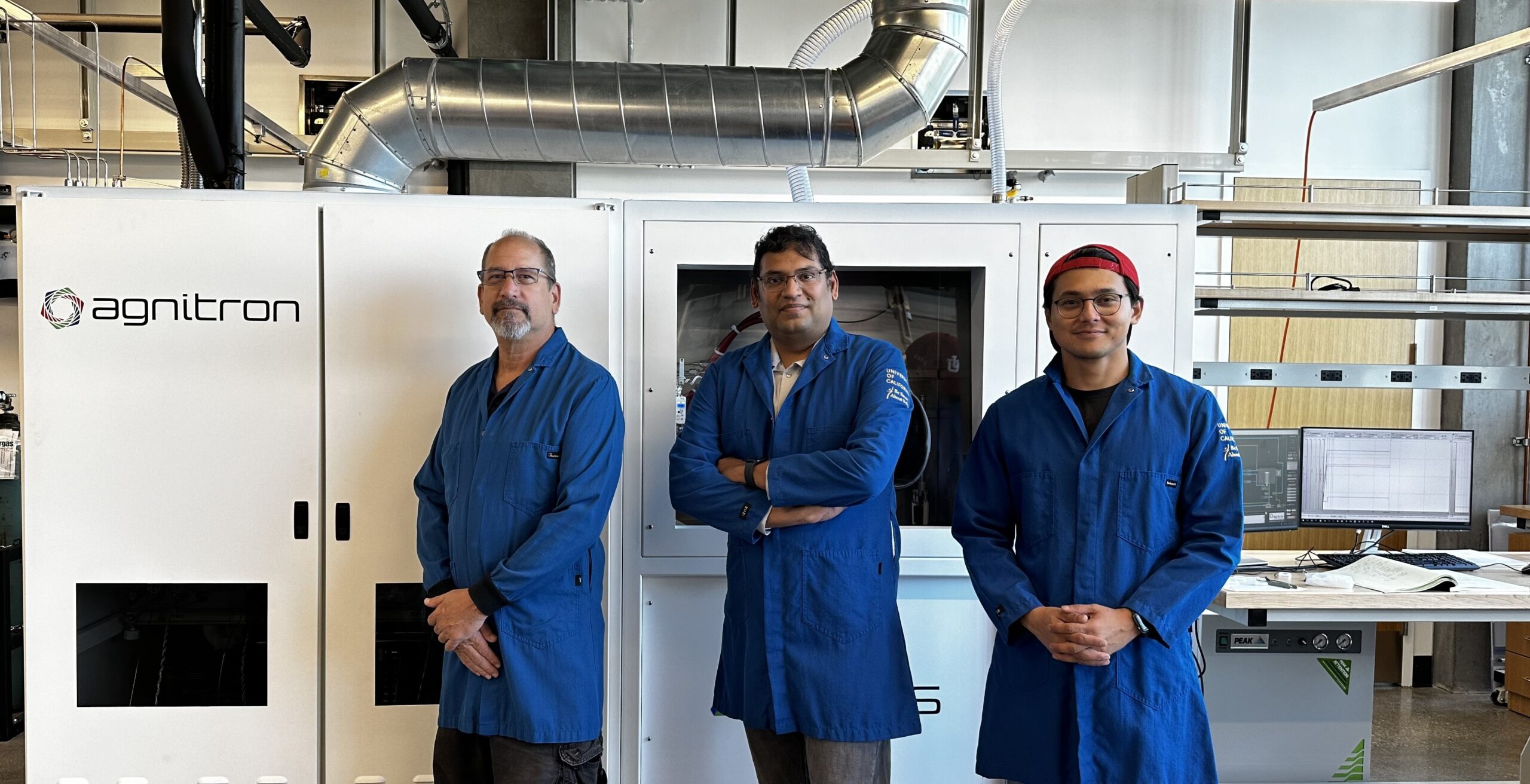

Agnitron installed and qualified the R&D gallium oxide MOCVD Agilis 100 system in July 2023 at UCSB. Agnitron and UCSB have worked together for >5years on similar topics with various contracts but now UCSB can grow its own materials, providing greater flexibility and innovation. The Agnitron Agilis 100 system with six metal-organic channels, two oxidizing precursor lines and silicon doping capability at UCSB can perform growths up to a 1100 °C substrate process temperature. The system has a GEN II remote injection with a close injector showerhead add on, in-situ pyrometry and reflectometry for growth parameter control, and Agnitron’s state-of-the-art software control platform Imperium™. The tool has demonstrated significantly reduced gas-phase reaction vs. other technologies and excellent thickness uniformity on a two-inch diameter wafer. According to Agnitron, the Agilis 100 MOCVD platform is easily convertible to grow GaN and AlN epitaxial layers as well. This dual capability of the hardware and control software is an enabling feature for ultimate flexibility of the tool. Professor Dr. Sriram Krishnamoorthy chose Agnitron Agilis 100 for his research on Ga2O3 because of its proven track record, use by many other research groups world-wide, and its demonstrated excellent quality material. “We look forward to partnering with Agnitron to develop further epitaxial layers of ultra-wide bandgap Ga2O3, alloys and heterostructures and translate that to record breaking device performance. We are excited to repeat and improve upon our previous experience with Agnitron Agilis Gallium oxide MOCVD system at the University of Utah which enabled us to achieve the highest quality epitaxial films,” says Krishnamoorthy. Vice President of Sales, Paul Fabiano commented, “We are pleased to partner with UCSB on UWBG materials. It’s an important and expanding material system for future RF and power device technologies. UCSB has a leading university with these types of semiconductors.”

The Agnitron Agilis 100 MOCVD holds world records in material purity and crystal quality. Fabiano further commented that Agnitron is excited to support the new MOCVD tool at Dr. Sriram Krishnamoorthy’s laboratory at UCSB and their research to make advances in epitaxial grown Ga2O3. The tool is installed in Henley Hall, the home for the Institute of Energy Efficiency (IEE), an interdisciplinary research institute dedicated to cutting-edge science and technologies that support an energy-efficient and sustainable future. You can learn more about his UCSB lab at this link: https://sites.google.com/view/krishnamoorthygroup/home/group-news

Also, this summer, Agnitron delivered an MOCVD/CVD tool to Notre Dame University’s School of Engineering. This system, an Agilis Mini, will grow SiC devices for the development of the field of quantum computing. President and CEO of Agnitron, Andrei Osinsky says “the Agilis Mini was introduced this year by Agnitron to provide research groups with the same state-of-the-art attributes of the Agilis 100 but who have a more constrained budget. Overtime the tool can be enhanced and upgraded with other technologies however out of the box can meet the current R&D needs of the customer.” The Agilis Mini deploys the same innovations as Agnitron’s other growth systems but on a smaller scale. Dr. Chris Hinkle of Notre Dame comments “We needed a new tool to make the highest quality SiC for quantum interconnects. We chose the Mini-Agilis from Agnitron because of the company’s reputation and the tool design being able to provide the purity needed for long-lifetime qubits.

The tool (pictured here) is being installed in an Engineering Clean Room at the University’s campus. The building houses numerous other types of semiconductor equipment and laboratories, used by students and faculty.

Agnitron has a large and growing installed base of Agilis 100/500 &700 MOCVD systems that’s resulted, since its inception, in more than 150 published research papers and delivery of approximately 100 conference presentations.

Agnitron Technology, Inc. is a compound semiconductor technology company and supports MOCVD equipment-related needs of R&D and production users. Agnitron’s Agilis Series MOCVD equipment offers configurations which support material growth capabilities for III-N, As/P, oxide, 2-D/TMD and many other related materials. The Agilis MOCVD tool can accommodate single or multi-wafer loading capacity reactor options; it is available for the general market. Agnitron also performs contract III-N and oxide R&D services at their MOCVD growth laboratory in Chanhassen, MN. Visit Agnitron’s website at www.agnitron.com or contact sales@agnitron.com for more information about their products and services.