Agnitron Releases Next Version of IMPERIUM-MOCVD Control Software and Automation

FOR IMMEDIATE RELEASE

August 9th, 2013, Eden Prairie, MN

Ultimate control, unparalleled flexibility, supreme process stability.

Agnitron Technology, Inc. announced today release of its second generation IMPERIUM-MOCVDTM Control Software and Automation package. New features in the release enable unparalleled flexibility and awareness for operators about system status and process conditions. These new capabilities enhance process control and repeatability as well as safety. IMPERIUM-MOCVDTM is currently being used at production sites and commercial and academic research facilities around the world. Standard software features include the following.

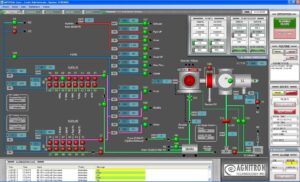

- Graphical Schematic Display enables viewing of system status and operation or manual control for growth processes including gas flows, MO source pressure, MO bath temperature, reactor chamber status (susceptor temperature, reactor pressure, water-cooling temperature etc.), exhaust system status and load lock functions.

- Configurable digital outputs for safety interlocks automatically shutdown the system in the event of an emergency or unsafe operating conditions – can also be configured to communicate and trigger facility alarms.

- PC can be networked to provide remote monitoring of system status, events and alarms etc.

- All analog and digital input and output signals are saved to process data log during execution of programmable recipes.

These features enjoyed by users of the original IMPERIUM Control Software and Automation version remain the foundation of all IMPERIUM versions today but this release adds a number of capabilities that enhance system and process monitoring and control. The familiar, Graphical Schematic Display interface remains the face of IMPERIUM and continues to deliver clear and comprehensive system information and manual operation. The new capabilities delivered in this release include the following.

- Fully configurable system routines allow users to add/remove steps as well as change sequence and values of routine parameters.

- Alarms and notifications for analog controls that notify user if value deviates from specified value(s).

- Plotting function for visualizing any real-time analog control value or data from Process Data Log

- Sortable and exportable Event and Alarm Logs.

- Integrated feedback control of recipe parameters by data from k-Space, RealTemp, LayTec or other insitu metrology system.

- Real-time in-process recipe modification.

- Dual-monitor display enables operator to view multiple tabs for enhanced awareness and efficiency.

The IMPERIUM Control Software and Automation product line provides unparalleled configuration flexibility for tool owners. Multiple deployment options are available to allow IMPERIUM to interface with network based IO systems such as DeviceNet or traditional PLC I/O platforms. Updating legacy hardware with an IMPERIUM control system enables state of the art processing at a fraction the cost of purchasing a completely new system. Three variation of the Control Software and Automation are currently offered: IMPERIUM-MOCVDTM, IMPERIUM-PLASMATM and IMPERIUM-PVDTM. Out-of-the-box customization features enable software setup to precisely match unique hardware setups. Configuration is supported for most major types of semiconductor industry processing equipment.

Agnitron Technology, Inc. specializes in developing emerging compound semiconductor material and device technologies into profitable commercial products as well as economical custom MOCVD equipment solutions. Their diverse team and partners draw from backgrounds in physics, materials science, semiconductor processing and electrical and mechanical engineering. Collectively, this team is credited with more than 400 published manuscripts and over 50 patents.

For more information contact Ross Miller, Director of Technology Development, at ross.miller@agnitron.com or visit www.agnitron.com.