Agnitron Products

Agnitron’s laboratory has enabled the research and development of the most advanced MOVCD systems and critical components, Control Software and Automation and insitu monitoring. Our systems are designed to meet your R&D requirements for Ga203, GaN and many other alloys for a range of applications. We also offer custom systems to meet your needs.

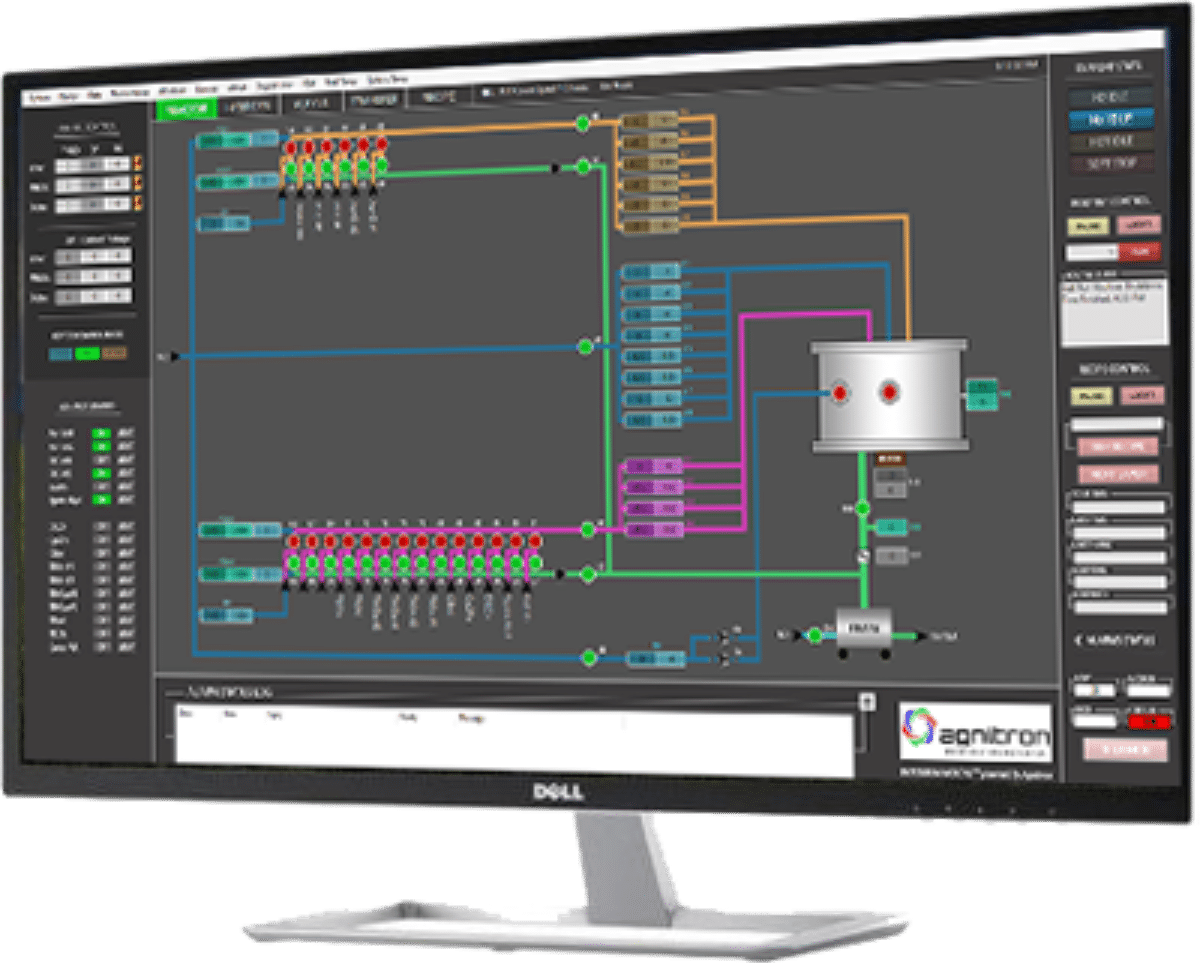

Imperium Control Software and Automation was developed to extend the life of legacy CVD systems and upgrade them with state-of-the-art control and data logging capabilities to get much more out of these large capital investments. Imperium-MOCVD can replace Legacy Emcore, Veeco, Thomas Swan, Aixtron, TNSC and SMI OEM Control Software and Automation, while offering many new features.

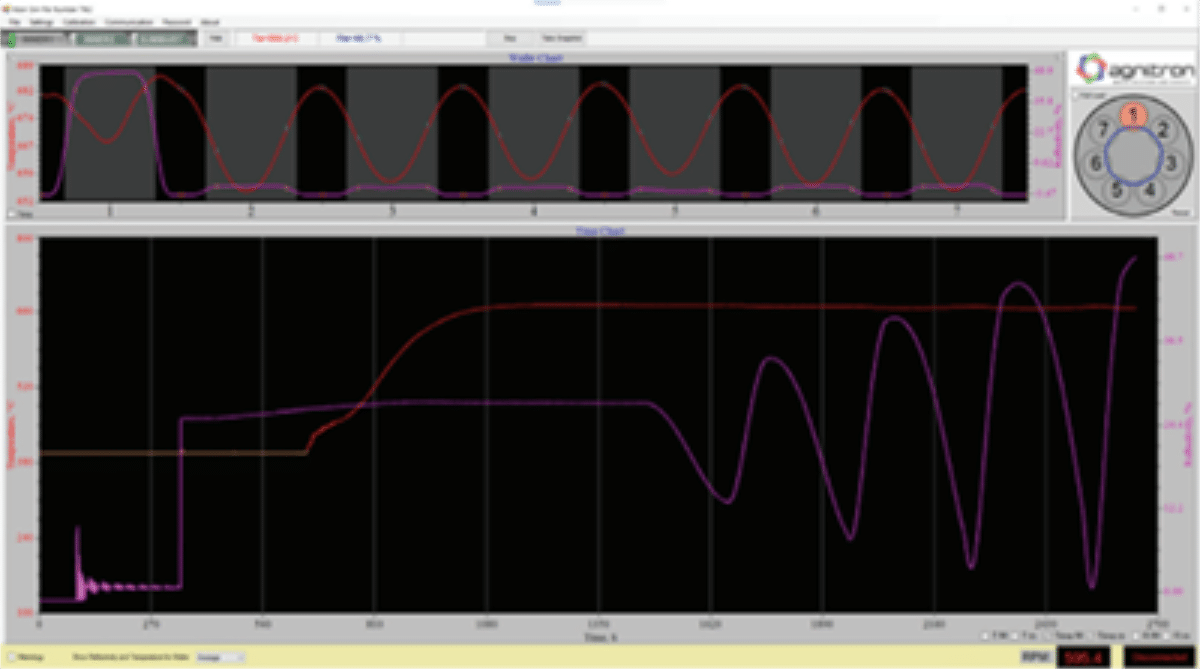

The Agnitron AgniTemp Multiwave Pyrometer provides the highest speed and accuracy measurements and control in demanding MOCVD systems.

MOCVD

Agnitron has a research and development MOCVD/CVD laboratory which supports the development of new MOCVD critical components. Using the laboratory Agnitron is also able to provide services for the growth of custom epitaxial structures based on Ga2O3, GaN, and related alloys for power electronic devices and UV photodetector.

Control Software and Automation

Imperium-MOCVD™ Control Software and Automation is a modern Windows operating system based SCADA package for controlling MOCVD equipment and processes. It was developed for extending the life of Legacy CVD (or any custom) systems and upgrading these large capital investments with state of art control and data logging capabilities.