R&D MOCVD

Agnitron has a research and development MOCVD/CVD laboratory which supports the development of new MOCVD critical components. Using the laboratory Agnitron is also able to provide services for the growth of custom epitaxial structures based on Ga2O3, GaN, and related alloys for power electronic devices and UV photodetector.

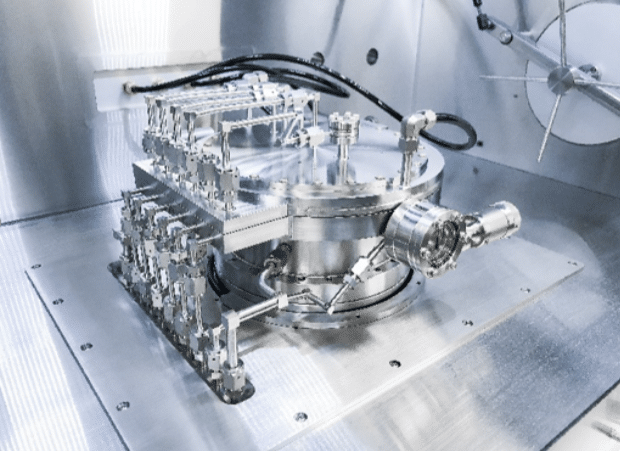

Custom Systems

Agnitron has been working with the military (AFRL & ONR) on advancing GaN growth processes for power device technology. Agnitron is currently building an advanced equipment system capable of activating the p-type GaN material for a wafer of at least 4″ in diameter for making ultra-high power vertical power electronic switches.